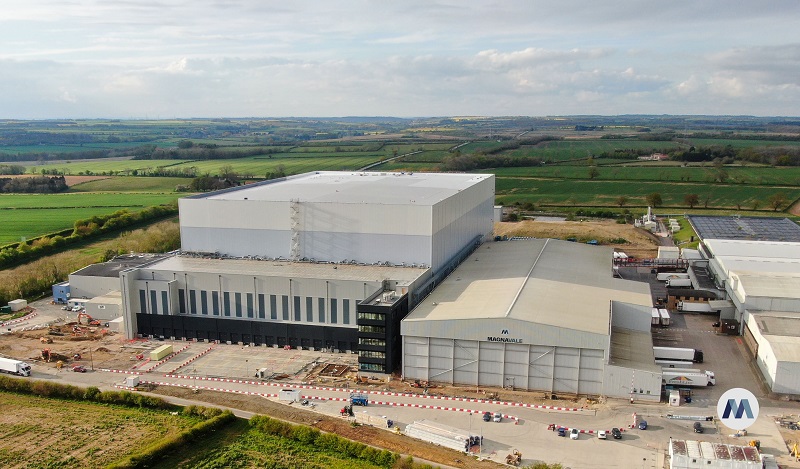

Building Exterior Now Completed for Magnavale Easton Cold Store

Cold Chain Federation member Magnavale, a leading provider of temperature-controlled storage solutions, today announced a significant milestone in the construction of its new state-of-the-art facility, Magnavale Easton. With the finish line rapidly approaching in Q3 2024, the company is pleased to confirm that the external structure of the 101,000-pallet temperature-controlled facility is now complete.

Along with the completion of the cladding, the Magnavale areas of the Sadel Food Hub are taking shape, with the yard works, including the car park, truck park, and internal roadways, progressing steadily in the background throughout the spring and early summer.

“Seeing the external structure of Easton complete is a huge milestone for all the teams that have been working on the development, and our Maganavale Easton team already working on site who are seeing the site being rapidly regenerated,” said Amanda Cogan, Chief Operating Officer at Magnavale. “Once operational, the facility will play a critical role in supporting food production in Lincolnshire as well as surrounding locations.”

A crucial component of this new facility is the installation of an oxygen reduction system, which is currently underway. This cutting-edge technology ensures that it is almost impossible for a fire to start, thereby safeguarding stock from fire and the water damage associated with traditional sprinkler systems.

Magnavale has partnered with Swisslog, a leading automation solution provider, to implement a highly advanced automated storage and retrieval system. With the racking, monorails and control systems now installed, extensive testing and commissioning is now being undertaken. The first test pallets have successfully already made their way from the loading bays into the high bay and back out for dispatch, displaying the system’s impressive functionality.

Developed by industry experts, the temperature-controlled facility has been designed to prevent disruptions during peak operational periods like the Christmas season, with multiple pallet ingress and egress points to avoid bottlenecks, as well as built-in redundancy planning with no single point of failure.

“As we approach the final stretch, our team remains dedicated to delivering a world-class temperature-controlled facility that will revolutionise our operations and set new standards in the industry,” added Amanda Cogan.

For more information about temperature-controlled storage at Magnavale Easton, please visit www.magnavale.co.uk or email enquiries@magnavale.co.uk.

Comments are closed.