Cold Chain – The First Line of Defence

Shane Brennan, chief executive of the Cold Chain Federation, discusses the critical role of the cold chain in a warming world, how we need to rethink and rebuild it and the part to be played by data and AI.

This article first appeared in SHD Logistics Magazine and was published online here on 12th November

It was a real privilege to speak on Centre Stage at this year’s IMHX. I found the technology and services showcased over the four days really inspiring and it gave me great confidence for the future of our industry. We are going to need every inch of that innovation and entrepreneurial drive if we are to meet the challenges that were the theme of my presentation – managing the cold chain in a warming world.

Cold chain is the main defence against one of the main evils causing climate change – food waste. We waste a third of the food we produce, think of the deforestation, the nitrogen and energy inputs and methane emissions involved in producing hundreds of millions of tonnes of food that no one ever eats.

Producing food, keeping it safe and getting it to the consumer will be much harder in a warming world. As Professor Toby Peters at University of Birmingham has shown the amount of ‘cooling’ (which combines air conditioning and refrigeration) required to service an exponentially growing and more affluent global population will mean we will need three times as much cold chain in 2050 than we have today. The implications of this growth in energy use and consequent potential carbon emissions on our global climate targets do not bear thinking about. We simply have to do things differently.

It is easy to think that the UK is not on the frontline of this challenge. We have a robust cold chain, sound infrastructure and the wealth to source and transport food from a range of domestic and international sources. Food security is quite a long way down the official register of climate change risks facing the UK. This should not be cause for complacency, that situation could change very quickly. The businesses and infrastructure will not just continue to exist, securing their future requires long term planning and sensible regulation.

The challenge of delivering the cold chain of tomorrow relies on two things ̶ innovation and investment.

What should we be investing in, when and how will we pay for it? The fact is that the whole UK population relies on a thin layer of specialised businesses, operating on tight margins, to keep it moving and keep it safe, operating from premises plenty of which are old, inefficient or not fit for purpose. As we consider the ways the supply chain must be rethought and rebuilt, we should not lose sight of the fact that we need to build an effective business case for doing it.

This is particularly challenging for buildings, generally speaking, design, construction and plant for buildings has got more efficient year-on-year. Basic construction and design principles haven’t changed radically, but incremental improvement in plant performance, monitoring and insulation of buildings means that the best new facilities can be 30-40% more efficient than traditionally built warehouses. It’s not as simple as new is best, but it is increasingly obvious that, in order to combat rising energy costs and increased regulatory pressure, a systematic programme of replacement of our facilities will be necessary over the medium to long term.

The electrification of vehicles is well underway, ambitious deadlines have been set for removing diesel and petrol cars from the road. The course towards electrified or alternative powered heavy goods vehicles is not so clear. In the short term the pressure is on increasing the efficiency of the use of the vehicles that we currently use, especially in urban areas. Rethinking how we get goods from A to B via C, using voluntary or even forced, consolidation is very much on the agenda. Businesses that embrace this are likely to prosper.

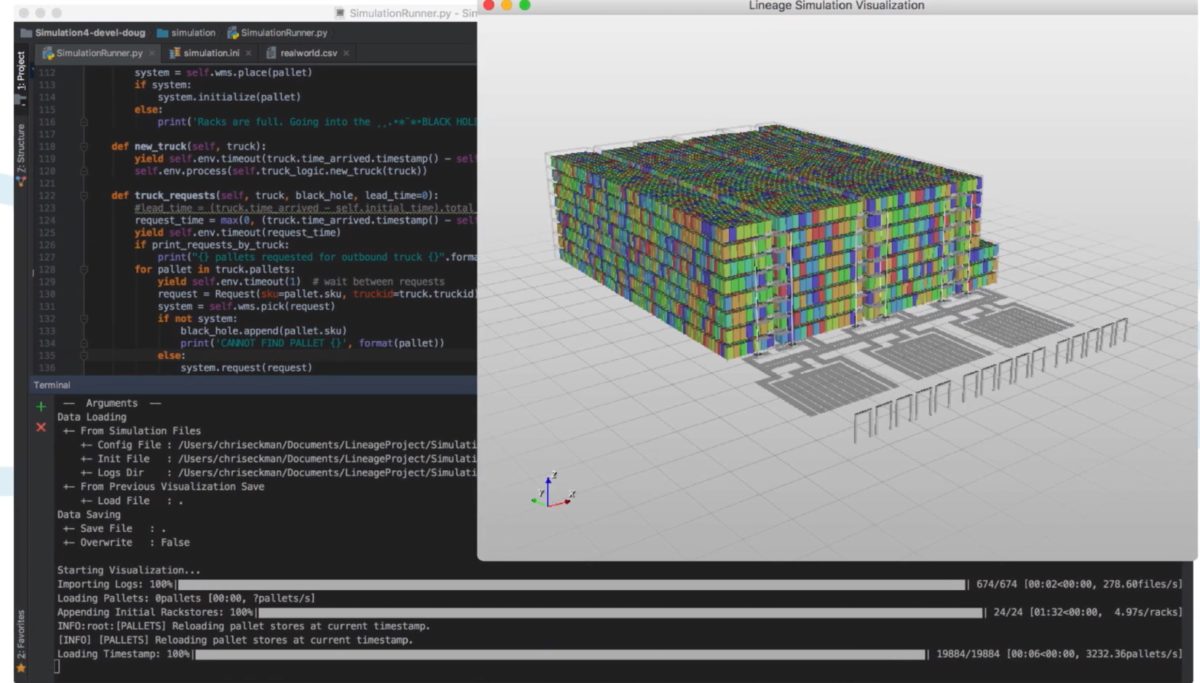

The technological revolution that has the most potential to change the cold chain is in data and artificial intelligence. By giving businesses at all stages of the chain the potential to manage and simulate, in granular detail, the inputs and performance of buildings, vehicles, labour, product (and pretty much anything else) the potential for marginal gains are significant. Aggregated together these gains will be transformational. But we should not underestimate the scale of the commitment and cultural change required to turn this potential into reality.

At a time of climate change… emergency… crisis (take your pick) the cold chain is a vital frontline defence. The UK will continue to lead the world developing and exporting technology, systems and skills, but only if we address ourselves fully to the challenges in our own backyard. It requires of us unprecedented levels of collaboration – between all parts of the chain and between industry and government. It also requires the kind of long term thinking and planning that do not come naturally to supply chain businesses that are so focused on getting things done today.

It’s an existential challenge, full of opportunity and purpose. It’s why we created the Cold Chain Federation and I am more than confident that we are up to the challenge.

Leave a Reply

You must be logged in to post a comment.