Coping with 40°C: Strategies for refrigeration plant owners

Written by Tom Woolston and Josh Collins, Technical Sales Engineers at Star Refrigeration.

As the effects of global warming continue, temperatures are projected to regularly exceed 40° Celsius in some parts of the UK. It will be critical for plant owners to plan ahead and address the critical challenge of keeping refrigeration systems efficient, reliable, and resilient under extreme heat. Without proactive planning, plants risk breakdowns, higher energy costs, and potential product loss. This article outlines proven strategies to help you prepare your refrigeration systems for higher ambient conditions.

Initial refrigeration plant design parameters play an important role, as each plant must be prepared for higher ambient temperatures. Of equal importance is the implementation of proactive aftercare, which can help ensure reliable and energy-efficient performance during hot summer weather. Modern AI and live-data analysis technology, which processes millions of data points in seconds, further improves this by converting real-time data into actionable insights, identifying inefficiencies, and enabling refrigeration maintenance teams to carry out targeted maintenance interventions to sustain performance during high-temperature periods.

Several important factors must be considered when preparing to effectively cope with temperatures of 40°C. The primary focus is maintaining continuous operation during peak temperatures, which depends on both technical measures and a strong in-house culture centred on minimising heat ingress and retaining cold air. This operational discipline reduces cooling demand and supports energy-efficient, reliable performance under extreme conditions.

What’s the impact of 40°C on refrigeration system performance?

The maximum temperature measured in July 1976 was approximately 32°C, but by August 2003, localised spots were reaching highs of 36°C. The highest daily maximum temperature increased from 33.3°C in 2010 to 40.3°C in 2022, with six consecutive days above 34°C recorded in 2020. The second warmest year on record for the UK was in 2023.

The highest ever temperature on record, 40.3°C, was recorded on 19th July 2022, and experts state that if climate change continues at its current rate, by 2050, the future UK weather forecast will regularly see temperatures of 40°C and beyond.

According to the Met Office, businesses now face the dual challenges of reducing emissions while managing the risks associated with the transition to a low carbon economy, at the same time as they attempt to adapt to changes in our climate.

As we reach the height of summer, refrigeration systems are placed under pressure to maintain safe operating temperatures for office buildings, storage facilities (e.g. food, beverages and pharmaceuticals) data centres and other temperature control environments. Therefore, rising temperatures present challenges for plant reliability, an increased risk of equipment failure and higher energy consumption. Several key factors contribute to the increased strain placed on refrigeration systems:

- Higher ambient conditions cause refrigeration systems to reject their waste heat to the air at higher temperatures, often surpassing the design parameters. Many plants, particularly those installed in the 1990s and early 2000s, were designed for maximum ambient temperatures of 32 degrees Celsius or less.

- Elevated condensing pressures reduce compressor capacity, resulting in the equipment running for longer or an inability to maintain the design cooling temperature.

- High ambient temperatures also leads to higher energy consumption, as the compressor must work harder to maintain the same conditions.

- The combination of longer and harder running conditions ultimately reduces the compressor’s life expectancy and increases the possibility of faults and/or early replacement.

- High condensing pressures can also lead to plant faults, including high-pressure faults. These faults often require an engineer to visit the site to analyse and reset the system, leading to expensive refrigeration plant downtime.

Case study: A real-world example demonstrates how hotter summers lead to increase energy demand.

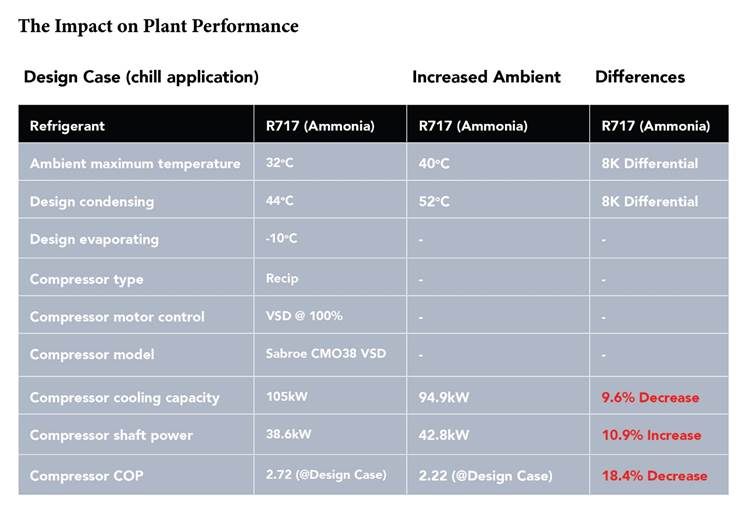

An ammonia chill application system was originally designed for a maximum ambient temperature of 32°C, a condensing temperature of 44°C and an evaporating temperature of -10°C. The compressor cooling capacity at these conditions was 105 kW, with a compressor shaft power of 38.6 kW and a coefficient of performance (CoP) of 2.72.

When the ambient temperature rose to 40°C, the design condensing temperature increased to 52°C. As a result, the compressor cooling capacity dropped to 94.9 kW, shaft power increased to 42.8 kW, and the coefficient of performance (CoP) fell to 2.22.

The 9.6% reduction in compressor cooling capacity, 10.9% increase in shaft power, and 18.4% decrease in CoP resulted in the plant operating 10% longer and consuming 11% more energy to deliver the same cooling output.

How can plant owners future-proof systems for 40°C?

The impact of high ambient temperatures on refrigeration systems can be mitigated by focusing on three critical factors: refrigeration system and cold storage design, cold and chill store management, and maintenance practices.

- Advanced refrigeration system and temperature controlled building design

A holistic approach to temperature-controlled buildings’ efficiency and resilience starts with early planning and extends through construction, system design, maintenance, monitoring, and continuous optimisation.

a) Planning: Site layout, plant room location, and condenser positioning can significantly reduce heat ingress.

For example, positioning loading bay doors away from direct sunlight and relocating heat-generating activities, such as forklift operations outside of temperature-controlled areas can substantially decrease cooling demand and energy consumption. Likewise, suitable placement of condensers to avoid heat exposure is also essential. Locating a refrigeration system on the north-facing side of a building, out of direct sunlight for most of the year, will significantly reduce the heat load compared to south-facing or roof-mounted setups.

The integration of renewable energy sources such as solar or wind power to offset energy consumption, especially during peak demand, provides an additional buffer. Inclusion of waste heat recovery systems and/or heat pumps can also reduce or even remove the need for gas fired heat sources.

End users must also ensure that the system is properly sized and designed to perform efficiently at 40°C. This includes provision of a suitably sized electrical supply to enable operation in higher ambient conditions.

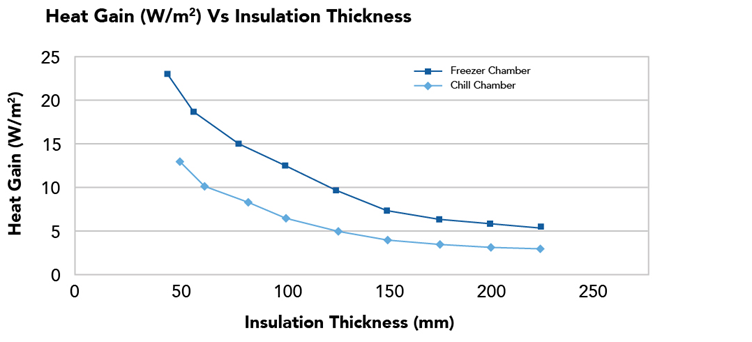

b) Construction: Selecting appropriate insulation and building materials is critical. The thickness and type of insulation can greatly influence the building’s thermal performance. While insulation of 50 mm thickness offers a heat gain of 25 W/m², installing insulation of 200 mm thickness and above provides a heat gain of just 5 W/m².

Proper sealing and jointing vapour seal techniques during construction are important to prevent future heat gains through structural weaknesses. Roof materials should also be considered, as reflective or lighter coloured materials can significantly reduce heat absorption compared to darker ones.

c) Refrigeration System Design: Designing a refrigeration system to handle ambient temperatures of 40°C instead of 32°C-35°C has significant implications on performance during high temperature periods. It provides greater resilience during extreme higher ambient conditions and at the same time delivers more efficient and reliable operation when ambient temperatures are lower. This is due to the higher heat rejection capacity (compared to a lower ambient system design) and operating under less strenuous conditions for the majority of the year.

The choice of refrigerant is crucial, as it affects the final system’s efficiency, capacity, environmental footprint, and compliance with current and future regulations. Naturally occurring fluids, including ammonia, CO₂, and hydrocarbons, all fall into the category of ‘long-term’ refrigerants, but their efficiency can vary depending on the application. For example, +40°C will result in CO₂ operating for longer at transcritical conditions, which results in far lower efficiency than ammonia under the same conditions.

- Site Management: Effective temperature controlled building operation during high temperatures requires a strong internal culture focused on energy efficiency and temperature discipline. This includes strategies to minimise heat load, keep cold air contained within the facility, and prevent warm air ingress.

a) Heat Load Management: Building insulation, door seals, and prevention of warm air ingress are critical. Thermographic scans can identify problem areas of heat ingress in the building fabric, allowing for timely repairs and upgrades to improve overall system performance.

Air Ingress: Leaving gaps around trailers when opening loading dock doors results in air ingress into the facility as higher pressure, warm air flows into the lower pressure, colder building. This results in higher maintenance and electricity costs.

Case Study: Loading dock heat ingress

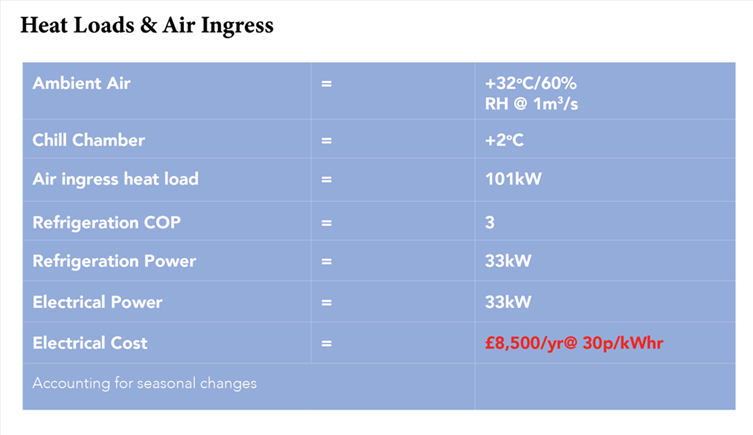

In the following case study, a mixture of poor-fitting trailers and damaged loading dock doors resulted in air ingress into a +2°C chill chamber.

At an outside temperature of 32°C and 60% relative humidity, a 1 m3 gap around the loading dock door allowed approximately 101 kW of heat to enter the chamber. Removing this excess heat required around 33 kW of refrigeration power. If this were allowed to continue for a year, then based on electricity costs of 30 pence per kilowatt/hour and accounting for seasonal variations, this additional load would have translated into annual energy costs of around £8,500. This demonstrates the significant financial impact of ensuring loading dock doors are properly sealed.

Door Control: The height of the door, frequency of use, and open duration all impact heat ingress. Closing a door within 5 seconds instead of 20 can reduce heat load by 75%. Strip curtains or airlocks provide an additional layer of protection.

b) Product, equipment and people heat loads

Incoming product temperature, electrical equipment, and personnel activity all contribute to heat load.

Products entering temperature-controlled buildings at temperatures above the chamber setpoint contribute additional heat load, increasing both cooling demand and energy consumption.

Monitoring incoming temperatures is particularly important during the summer months, when the rest of the cold chain may also be exposed to higher ambient temperatures, which can impact the arrival temperatures of products.

c) Electrical Loads

Replacing inefficient lighting and switching off unused equipment can result in significant savings. One example showed that replacing 250 W lights with 48 W LEDs saved 80% in lighting energy, while switching on and off eight 1.5 kW booster fans that ran continuously saved 105,120 kWh/year, or £31,500, with no performance impact.

d) Night-time cooling

Taking advantage of cooler evening temperatures to pre-cool stores reduces energy use during daytime peaks and improves overall efficiency

3 Maintenance and monitoring

A structured maintenance plan will outline the necessary short-term actions required to keep the plant operating efficiently during the summer months. It will also predefine the appropriate measures to address each specific type of failure and ensure that the stock already in the temperature-controlled building is protected in the event of an unexpected failure. Regular inspections and proactive maintenance will prevent breakdowns and ensure the plant functions optimally during heatwaves. This preparation is key for minimising energy usage and maintaining cooling capacity when temperatures soar.

Proactive maintenance strategies can help identify, prevent and fix technical problems to ensure optimum system performance. When combined with AI driven, live-data analysis technology using digital twin comparisons, maintenance regimes can optimise operation through targeted interventions and guided service schedules. Collaborating with refrigeration maintenance contractors experienced in this approach ensures effective and cost-efficient upkeep.

a) Benchmarking: Benchmarking current refrigeration system performance against similar stores across the country and the UK’s ‘Best Practice’ guidelines helps determine how your site measures up, and where there is room for improvement. Simple and effective tools like the freely available SEC calculator make it easy to compare a site’s performance against industry ‘Best Practice’ standards, competitors, or other sites within your estate.

b) Data Analysis and Monitoring:

AI-enabled, real-time data monitoring and analysis technology such as Ethos can pinpoint inefficiencies and recommend corrective actions, enabling maintenance teams and site managers to verify whether a cold or chill store is operating as intended or to apply targeted interventions that restore optimal performance.

Ethos integrates data from wireless sensors, enabling monitoring of refrigeration, heating, lighting, and doors under a single platform.

It can also provide a detailed view of system performance, trends, suggested corrective measures, and estimates of financial and CO₂ savings if remedial action is undertaken.

c) System Optimisation and Controls: Continuous fine-tuning of setpoints and controls based on historical and live site data can significantly enhance performance. Intelligent control and AI systems further improve efficiency by adapting controls to changing conditions.

Best Practices for maintaining refrigeration systems in high temperatures

Several factors can contribute to reduced plant performance and excessive power consumption during periods of hot weather. Below are some simple things to check:

Condenser conditions

Regular inspection of condensers helps ensure optimal performance and energy efficiency. For air-cooled condensers, keeping units free from dirt, leaves, and other debris is especially important, as their fan-driven design naturally draws in lightweight materials from their surroundings. Maintaining clean and undamaged fins helps preserve airflow, reduces condensing conditions, and extends running time, which translates into lower energy usage.

For evaporative condensers, maintaining consistent water flow, utilising proper water treatment, and keeping the packing well-maintained are crucial to achieving reliable heat rejection throughout the year. Monitoring these helps prevent performance losses caused by blocked nozzles or restricted flow, while effective water treatment reduces the risk of fouling on condenser coils, which can act as insulation, ensuring the unit continues to reject heat efficiently and operates at peak capacity.

A minimum of two cleans per year, in spring and autumn, is recommended; however, additional cleaning may be necessary depending on the condenser’s location.

Low refrigerant levels and poor refrigerant quality

A reduction in refrigerant charge can occur due to refrigerant leakage or failure to recharge to the correct level after service or maintenance work. Operating at suboptimal levels can reduce both heat transfer and compressor performance, resulting in equipment running for longer periods of time and higher electrical consumption.

Refrigerant quality checks are particularly important to prevent equipment failure caused by refrigerant contamination. Impurities, non-condensables and high moisture content in the refrigerant could lead to a severe loss of cooling capacity and rising energy costs.

In the case of ammonia, water contamination of 1% or less is acceptable, provided it is monitored. However, above this percentage, every 1% of water in the refrigerant increases the running costs of the cooling plant by 1%. If left unattended, this could also lead to a rapid breakdown of oils and component failure, resulting in a further increase in operating costs.

Oil recovery

It is essential to ensure that oil is effectively recovered and returned to the compressors to maintain their performance and prevent increased wear and potential damage. Accumulation of oil in other parts of the refrigeration system can affect both the compressor and the heat transfer process. For example, the logging of oil in plate heat exchanger evaporators or air coolers reduces the available surface area for cooling, increasing running time and the energy required to deliver cooling.

Iced up evaporators

Iced-up and fouled evaporators, produced by a combination of poor door management, ineffective defrosting, and moisture ingress, can lead to reduced heat transfer, increased risk of leakage, and excessive site temperatures.

Compressor operation, pressures and temperature

Compressor operation, pressures, temperature, and loading must all be assessed, while evaporators and room coolers must be cleared of ice and debris, with fans and control valves checked.

Temperature set points

Regular review and adjustment of temperature set points ensure they are adequate for current usage without overburdening the system, thereby avoiding higher energy costs.

Liquid Pumps

Liquid pumps, including those used in glycol systems, benefit from continuous monitoring of key parameters such as pump differential pressure. This can help identify poor performance or blocked strainers before a pump faults or fails. Regular checks on fluid condition and vibration levels are also crucial for maintaining optimal performance and reliability.

Monitoring system performance and energy use

Assessing current performance against historical data and industry benchmarks will identify gaps in performance and highlight areas for improvement, increasing the operator’s ability to prepare their refrigeration systems for high ambient temperatures.

Conclusion:

The prospect of regular summer temperatures of 40°C or higher is now a reality. Refrigeration plant owners must assess whether their systems are operating within design limits, whether performance gaps have been addressed, and whether maintenance strategies are aligned with current risk. Monitoring, proactive planning, and the use of intelligent controls and AI-driven, live data analysis technology are essential to ensure reliability, energy efficiency, and long-term resilience in a warming climate.

This article has been CPD certified by the International CPD Certification Service. To obtain your CPD Diploma, please email [email protected].

Comments are closed.