The CCF’s Energy Benchmarking Project for cold storage is a long-term commitment to support the industry to reduce costs whilst saving energy.

For the past two years the Cold Chain Federation has been working with our partners at Jacobs Engineering to produce an energy benchmarking service for businesses that are part of the Climate Change Agreement (CCA) scheme.

We recognised the lack of freely available information for energy benchmarking a UK cold storage operation, with the few academic studies available either based on historic energy data, or from a relatively small and often non-UK, sample sizes. With over 450 cold stores reporting their verified energy usage to us annually, we are well placed to produce robust benchmarks for our members.

The specific aim of the CCF’s Energy Benchmarking project is twofold:

- to provide our members with an easy-to-use tool to help them understand the energy usage of their cold stores compared to similar facilities around the UK and to indicate what financial and carbon savings might be achieved with reductions in energy use.

- to publish high level results of cold storage energy benchmarks to support businesses outside the CCA to improve their energy efficiency, particularly those operating overseas.

We recognise that there is a significant degree of variability in how cold stores are operated which makes comparing them challenging, however we have taken measures to recognise these differences in how we have developed our cohorts, and in the bespoke tool we have provided to our members.

HOW WE CREATED THE CCF COLD STORAGE ENERGY BENCHMARKS

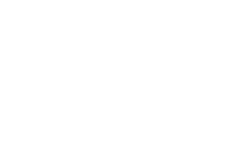

Each year, the operators of around 450 cold stores provide details of their annual energy usage and throughput (usually m3 of cooling space) to the Cold Chain Federation as part of their obligations under the Climate Change Agreement for cold storage.

This data is self-certified by operators for accuracy against the CCA scheme criteria and is subject to spot check audits by the Environment Agency. Criteria include that at least 70% of the energy data reported is used for the cold storage operation and directly associated activities (eg. refrigeration, lighting, forklift trucks).

Each cold store’s specific energy consumption (S.E.C.) is determined by dividing the total site (or the eligible) electricity consumption by the site cold storage volume, resulting in a kWh/m3 measurement for each facility. The higher the S.E.C, the lower the efficiency.

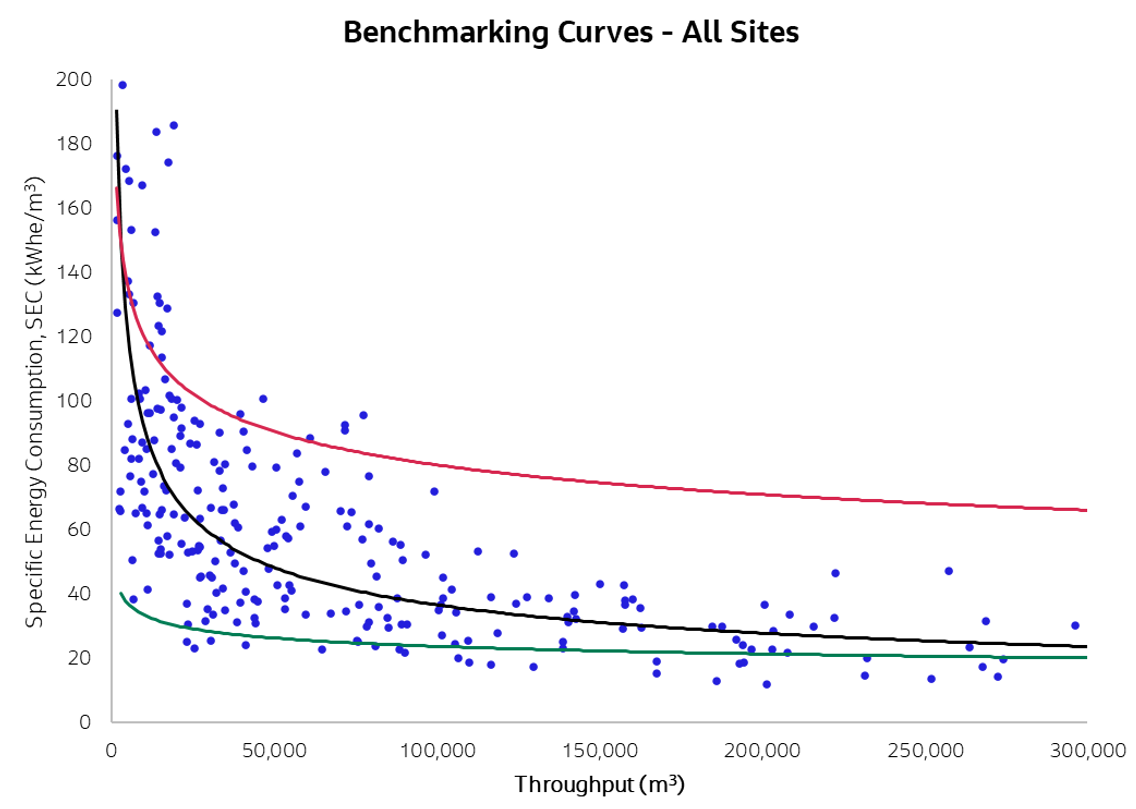

After consultation with our members, we have grouped cold stores into six cohorts based on their cooling volume and whether they are used for majority chilled or frozen products. Size categories were created to ensure roughly an even split of cold stores within each:

- Large: greater than 100,000m3

- Medium: 20,000m3 to 100,000m3

- Small: less than 20,000m3

HOW THE COHORT BENCHMARK IS CALCULATED

The cohort benchmark figure is the average S.E.C. across sites within each cohort. To avoid low or high S.E.C. sites skewing the benchmark figure, sites falling below or above the 10th and 90th percentiles of each cohort respectively were excluded from the benchmark calculation process (but they have had dashboards created for them).

We also created a ‘High Energy User’ and ‘Low Energy User’ benchmark based on the upper and lower quartiles of each cohort.

COLD STORAGE BENCHMARKS FOR 2023

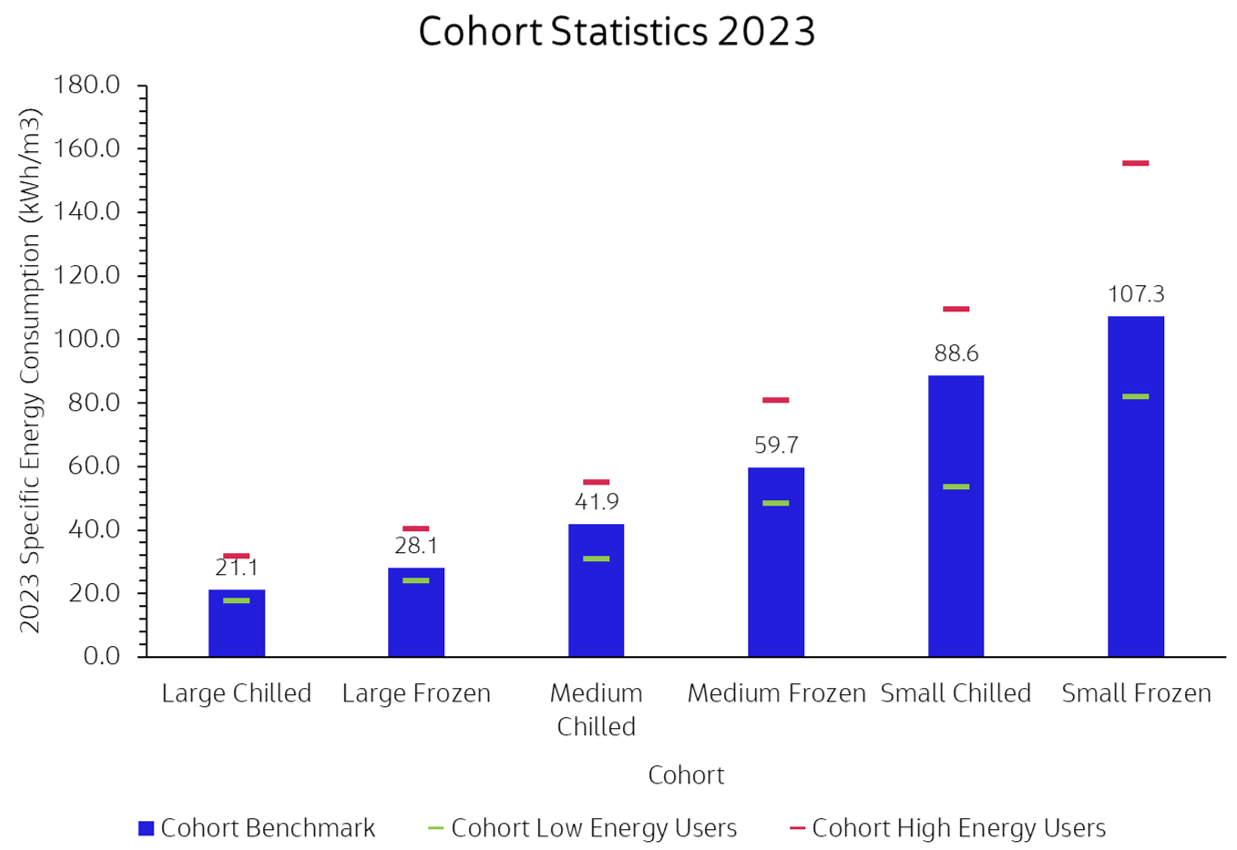

BENCHMARKING DASHBOARD FOR COLD STORAGE OPERATORS

The primary aim of the CCF’s cold storage energy benchmarking project is to provide businesses with a tool to help them understand how their site performs when compared to similar sites, and an indication of the cost and carbon savings available should they improve.

Every business has been provided with a bespoke dashboard providing them with this information. If you haven’t received yours, please get in touch with Tom Southall to discuss the options.

We recognise on site renewables (reducing grid energy usage) and energy intensive processes such as blast freezing (high energy, low storage volume) can impact a sites overall energy demand and benchmark performance. Although this is not yet recognised in the model, we have highlighted on relevant dashboards where this may be a factor to help with interpretation. We will look for ways to consider these factors in future updates.

COMMITMENT TO IMPROVEMENT

The CCF’s Energy Benchmarking Project for cold storage is a long-term commitment to support the industry to reduce costs whilst saving energy. We will update the tool again next year and continually improve our model to reflect the needs of our members. We value your thoughts on how we can continue to improve this service.

For more information on the Cold Chain Federation’s energy benchmarking service, please contact Executive Director, Tom Southall.